Automatic PP Bottle Blow Molding Machine

Description

The products made by Automatic PP bottle blow molding line don’t have any disfigurement. It can present the perfect mouth, bottom and line, as well as the better transparence and higher rigidity.

The standard operation of Automatic PP bottle blow molding line includes four steps as follow:

Step1. Put the preform into the preform container and the conveyer will take the preform to orientation units automatically.

Step2. Load the preform at neck up to preform holder, and then preform is conveyed into baking tunnel.

Step3. PP bottle blow molding line after heating, preform is conveyed into the blow station, then close the mold, stretch and blow under low pressure and high pressure, exhaust, open the mold.

Step4. The finished bottle is taken off by automatic discharging system.

Applications

With high quality and accuracy, our PP bottle blow molding line is used to produce medicine bottle, cosmetic container,health care products bottle, eye black tube and bottle for chemical use or pesticide. Now it is used by AVON, STARBUCKS COFFEE and sold in WALMART etc.

Pictures of the Ready-made

Series of Whirlwind WIB Injection-Blow Molding

Blow Molding Injection Preform

product Preform up

Advantages

1. Full-automatic character of the PP bottle blow molding machine make it is high automatically and the computer control system makes the hydraulic pressure work stable.

2. The automatic PP bottle blow molding line adopts the vertical work way to reduce projection area of the mold and use lower clamping pressure to finish the work, so as to achieve the effect of reducing energy consumption.

3. Double linear rolling motion guider in moving, opening and closing mold, making the clamping force equally distributed, so the cut is smoother.

4. Our PP bottle blow molding machine controls the hydraulic system with imported proportional valve, ensuring the action steady, accurate and energy saving.

5. High speed and efficient plasticizing system, mixing well and ensuring the produce purity.

Main Specifications of Automatic PP Bottle Blow Molding Machine

| NO | Item | Unit | Data | NO | Item | Unit | Data | NO | Item | Unit | Data |

| 1 | Screw Diameter | mm | 40 | 6 | Blow Clamping Force | KN | 32 | 10 | Compressed Air | Mpa | 0.6~1.2 |

| 2 | Screw Speed | r/min | 0~180 | 7 | Production Speed | pcs/h | 1100~2000 | 11 | Cooling Water | bar | 1~3 |

| 3 | Theoretical Injection Capacity | g | 150 | 8 | Motor Power | KW | 15 | 12 | Dimension of Machine | cm | 290×140×220 |

| 4 | Injection Clamping Force | KN | 200 | 9 | Heater Capacity | KW | 7 | 13 | Machine Weight | Kg | 4500 |

| 5 | Suitable Materials | PP | |||||||||

Product-related Configuration/ Parts

| No. | Item | Brand |

| 1 | All Hydraulic Valve | YUKEN |

| 2 | Variable Pump | YUKEN |

| 3 | Seal Ring | HALLITE |

| 4 | Hydraulic oil motor | INTERMOT |

| 5 | Cylinder Air Valve | SMC |

| 6 | Air Cylinder | SMC/AIRTAC |

| 7 | PLC | OMRON |

| 8 | Rotation Plant Servo Motor | OMRON |

| 9 | Low-voltage electrical components | Schneider |

| 10 | Temperature controller | OMRON |

| 11 | Material used for mould | Mould Stainless Steel |

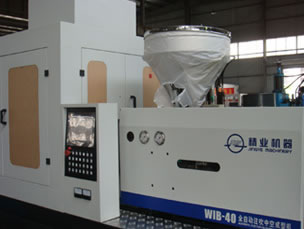

WIB-40 Automatic Injection Blow Molding Machine

WIB-40 Automatic Injection Blow Molding Machine WIB-40 Injection Blow Molding Machine

WIB-40 Injection Blow Molding Machine PE Bottle Blow Molding Machine

PE Bottle Blow Molding Machine Automatic PE Bottle Blow Molding Machine

Automatic PE Bottle Blow Molding Machine PP Bottle Making Machine

PP Bottle Making Machine PP Bottle Blow Molding Machine

PP Bottle Blow Molding Machine Medicine Bottle Making Machine

Medicine Bottle Making Machine Cosmetic Container Making Machine

Cosmetic Container Making Machine